Partial Enzymatic Hydrolysis of Starch to Maltodextrins on the Laboratory Scale

互联网

425

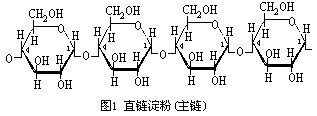

Starch mainly consists of amylopectin (70–80% w/w) and amylose (20–30% w/w). Amylopectin is a branched macromolecule (mol wt 107 –5.108 ) of which on average 1 in 20–25 α-(1,4)-bond glucose units is branched by an α-(1,6)-D -glucosidic bond. Amylose (mol wt 105 –107 ) consists of much longer linear chains of which on average one in several hundred α-(1,4)-bond glucose units is branched by an α-(1,6)-D -glucosidic bond (1 ). The hydrolysis of starch to low-mol-wt products catalyzed by an α-amylase is one of the most important commercial enzyme processes. The hydrolyzed products are widely used in the food, paper, and textile industry (2 ). The demand for hydrolyzed starches with specific functional properties has led to the development of a whole range of products. These are commercially available at relatively low prices from major starch producers. The reason to produce hydrolyzed starches on lab-scale will therefore mostly be either a kinetic study or the production of a product with a certain defined degree of hydrolysis. The degree of hydrolysis is expressed as dextrose equivalent (DE), which is the percentage of reducing sugar calculated as dextrose on dry-weight basis. The DE of, for example, glucose is 100 (by definition) and starch is virtually zero. Therefore, the dextrose equivalent is a measure of the mean average molecular mass of the starch hydrolysate. Maltodextrins are by definition nonsweet starch hydrolysates with a DE of < 20 (3 ). Starch hydrolysates with a DE above 20 are classified as glucose syrups.